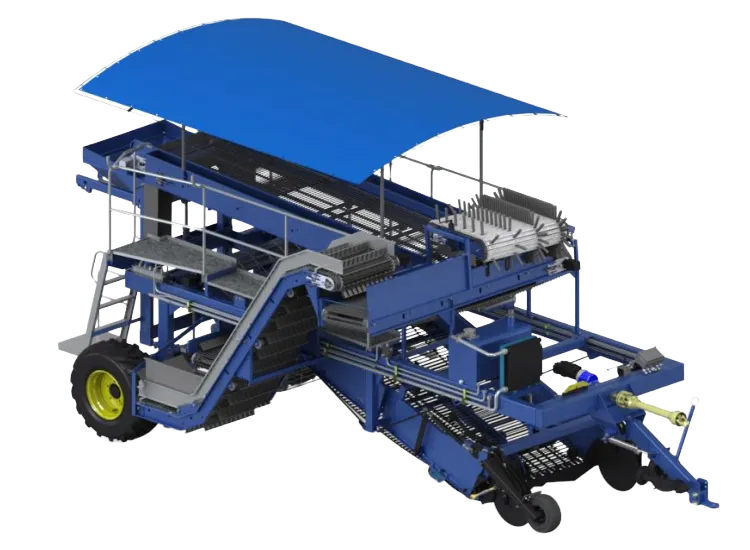

CWB-2L 2列式トラクター用ポテト収穫機

CWB-2L トラクター搭載型2列ポテトハーベスターは、中規模ジャガイモ栽培向けに設計された高効率のトラクター搭載型インプルメントです。調整可能な列間隔(70~90cm)、作物へのダメージを最小限に抑えるダブルチェーンシービング、そして3.5mの排出高さを備えています。100馬力以上のトラクター(540rpm PTO搭載)向けに最適化されており、時速2~5kmで安定した性能を発揮し、作業負荷を軽減し、多様な土壌条件における収穫量増加に貢献します。

| 技術データ | CWB-2L |

|---|---|

| 寸法 | |

| 長さ(mm) | 8800 |

| 幅(mm) | 3200 |

| 高さ(mm) | 3900 |

| 空重量 | 4500キログラム |

| トラクターの要件 | |

| カルダンシャフト入力回転数 | 540回転 |

| エンジン出力(分) | 100馬力 |

| 制御弁が必要 | 2 |

| 作業速度 | 2~5 km/h |

| 行容量 | 2行 |

| 行間隔(調整可能) | 70~90センチ |

| ふるい分けウェブタイプ | ダブルチェーンコンベア |

| 排出コンベアの高さ | 最大3.5メートル |

| 油圧システム | 2つのバルブを備えた独立型 |

CWB-2Lトラクター用ポテトハーベスターの概要

CWB-2L トラクター搭載型2列ポテトハーベスターは、ヨーロッパの中規模ジャガイモ農業向けに設計された高効率ソリューションです。このトラクター搭載型ポテトハーベスターは、堅牢な構造と高度な収穫技術を融合させ、作物へのダメージを最小限に抑え、収穫量を最大限に回収します。100馬力以上の標準トラクターに対応できるよう設計された本機は、540回転のカルダンシャフト入力によりスムーズな動力伝達を実現し、様々な土壌タイプにおいて信頼性の高い性能を発揮します。全長8,800mm、全幅3,200mm、全高3,900mmというバランスの取れた寸法は、圃場での容易な操作性と作業中の安定性を確保します。空車重量4,500kgは、過度の圧縮を伴わずに効果的に土壌を貫通し、持続可能な農業慣行に適しています。

主な特徴と機能設計

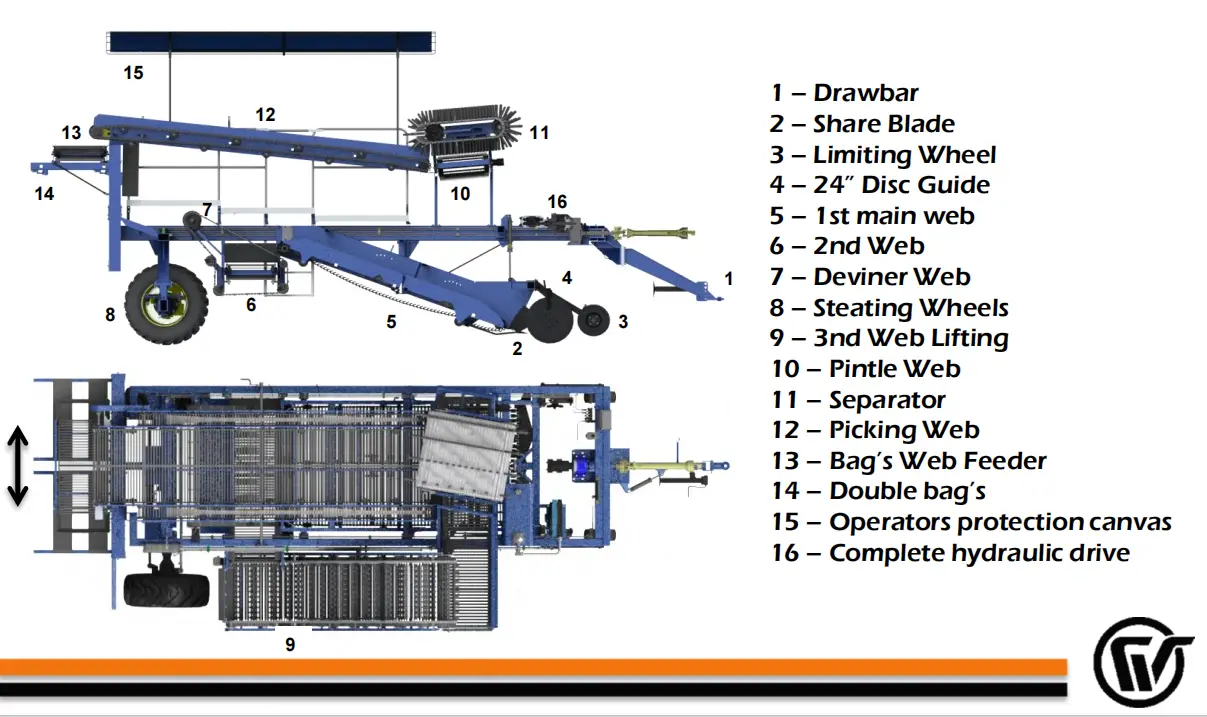

このジャガイモ収穫機の核となるのは2列収穫機能で、70~90cm間隔で植えた2列のジャガイモを同時に持ち上げることができます。これはヨーロッパのジャガイモ栽培の標準です。ふるい分けウェブシステムは、土や残骸からジャガイモを丁寧に分離するダブルチェーンコンベア機構を採用し、傷みを減らして作物全体の品質を向上させます。高さ3.5mまで調整可能な排出コンベアは、トレーラーや貯蔵容器への直接積み込みを容易にし、収穫プロセスを効率化します。独立した油圧システムは、2つの制御バルブのみを必要とし、掘削深さ、コンベア速度、排出機能を正確に制御し、作業効率を高めます。このトラクター牽引式ジャガイモ掘削機は、強化ガードや緊急停止機構などの安全機能も備えており、欧州市場のコンプライアンスのためのCE認証基準に準拠しています。

トラクターの適応とパフォーマンスの最適化

CWB-2Lトラクター用ポテトハーベスターは、最低エンジン出力100馬力のトラクターに最適化されており、幅広い農業機械に搭載可能です。540rpmのPTO回転数により、John Deere 6Mシリーズ、Fendt 500 Vario、New Holland T6モデルなど、ほとんどの中級トラクターとの互換性を確保しています。作業速度は2~5km/hで、徹底的な収穫と生産性を両立し、最適な条件下では1時間あたり最大1ヘクタールの収穫が可能です。カテゴリー2のボトムリンケージにより確実なアタッチメントが確保され、油圧需要は2バルブに制限されているため、トラクターシステムへの過負荷を防ぎます。最良の結果を得るには、重粘土質土壌では120馬力以上のトラクターを推奨します。4,500kgの重量を持つ本機は、掘削深を一定に保ちます。

製品の詳細と技術革新

製品の詳細を詳しく見てみると、CWB-2Lはモジュール設計を採用しており、メンテナンスと部品交換が容易で、運用寿命が延びています。ふるいチェーンは高張力鋼製で、調整可能なテンショナーにより土壌水分の変化に対応し、湿潤条件下での目詰まりを防止します。オプションで石分離装置を追加することで、ゴミの多い圃場でも収穫物の浄化をさらに進めることができます。本機はISO 9001製造基準の認証を取得し、EU機械指令にも完全準拠しているため、安全性と信頼性を確保しています。農業用ジャガイモ収穫機として、振動抑制技術を採用し、独立したフィールドテストに基づき、ジャガイモへのダメージを5%以下に抑えています。

応用分野と汎用性

この2列式ジャガイモ収穫機は、標準的なジャガイモ栽培に加え、様々な用途で優れた性能を発揮します。種芋生産においては、その優しいハンドリングにより塊茎の健全性を維持し、高付加価値作物を生産できます。有機農業においては、土壌に優しい設計により、有益な生物への影響を最小限に抑えます。オランダやベルギーなどのジャガイモ加工産業が盛んな地域では、最小限の労力で大量収穫を可能にします。CWB-2Lは、わずかな改良を加えることでニンジンやビートなどの他の根菜にも適応できるため、多様な農業活動においてその有用性を広げます。その汎用性は、複数の作物の収穫サービスを提供する請負業者にとって重要な資産となります。

実際のパフォーマンスを示すケーススタディ

CWB-2Lトラクター用ポテトハーベスターの威力を示す例として、オランダのフレヴォラント州にある200ヘクタールのジャガイモ農場の事例を挙げてみましょう。120馬力のトラクターにこの機械を導入した結果、単列モデルと比較して収穫時間が30%短縮され、収量回収率は98%に達しました。土壌分離は、この地域の粘土質土壌において特に効果的で、収穫後の洗浄コストを最小限に抑えることができました。別の例として、ベルギーの西フランダース州の協同組合の事例があります。この協同組合では、このハーベスターが150ヘクタールの早生ジャガイモを処理しました。調整可能な列間隔により、さまざまな植え付けパターンに対応でき、損傷率が低いため市場品質が向上し、プレミアムグレードの売上が15%増加しました。

3つ目の事例では、ドイツ、ニーダーザクセン州の請負業者がCWB-2Lを季節ごとの収穫サービスに使用しました。140馬力のトラクターと組み合わせたこの機械は、様々な圃場で時速4kmで稼働し、混合土壌条件における堅牢性を実証しました。独立した油圧システムにより、様々なトラクターモデルとのシームレスな接続が可能になり、運用の柔軟性が向上しました。これらの事例は、100馬力のトラクター用ジャガイモ収穫機が、実際のヨーロッパの農業環境においていかに安定した成果を上げられるかを示しています。

拡張された技術的洞察と認定

技術的な詳細についてさらに議論を進めると、CWB-2Lのカルダンシャフトは540rpmで動作し、最適なエネルギー伝達を実現することで、高効率トラクターでは最大20%の燃料消費量を削減します。ふるい分け機構には、土壌条件に合わせて可変速コンベアが組み込まれており、重粘土質土壌での過負荷や砂質ローム質土壌での土壌損失を防止します。製品の認定には、振動および騒音レベルの適合性を含むEU規格に基づく厳格な試験が含まれ、長時間の収穫作業でもオペレーターの快適性を確保しています。ジャガイモ掘削機として、人間工学に基づいた操作部と視認性の向上により、さまざまな地形での安全な操作が可能です。

メンテナンスと寿命に関する考慮事項

メンテナンスは容易で、給油箇所へのアクセスが容易です。また、コンベアチェーンなどの摩耗部品は交換可能で、平均的な使用条件で500時間以上の耐久性を備えています。粉体塗装仕上げは、湿度の高いヨーロッパの気候でも耐腐食性を発揮し、適切なメンテナンスを行えば10~15年の耐用年数を誇ります。ジャガイモ収穫機の価格をご検討中のお客様にとって、CWB-2Lは省力化と高い処理能力により優れた価値を提供し、中規模農場では2~3シーズンで投資回収を達成できるケースも少なくありません。

持続可能な農業への応用拡大

持続可能な農業において、このトラクター式ジャガイモ収穫機は、収穫時の土壌撹乱を最小限に抑えることで、耕起軽減システムをサポートします。GPS誘導式トラクターなどの精密農業ツールとの互換性により、正確な列追従が可能になり、圃場の構造を維持します。有機栽培農家にとっては、土壌との過度な接触による化学物質の残留を防ぎ、塊茎の品質を維持する優しいハンドリングが役立ちます。研究用途にも広がり、この機械はオランダで新しいジャガイモ品種の収穫効率を研究するための農業試験に使用されており、農業技術の発展におけるその役割を強く示しています。

ワタナベオランダ支店 – ポテト機械および関連製品のリーダー

ワタナベオランダ支店は、ワタナベ産業機械貿易株式会社のヨーロッパ部門として、50年以上にわたる農業機械の専門知識をジャガイモ農家や請負業者に提供しています。当社の製品ラインナップには、トラクター用ポテトハーベスターCWB-2Lだけでなく、THORシリーズなどの補完製品も含まれています。 トラクター式石破砕機 圃場準備用のEWシリーズロックレーキ、土砂除去用のEWシリーズロックレーキ、そして土壌耕起用のPSWロータリー。すべての機器はCE認証を取得しており、オランダ国内に在庫を保有しています。純正スペアパーツと多言語対応の技術サポートも提供しています。この包括的な製品ラインナップにより、植え付けから収穫まで、ジャガイモ生産チェーンへのシームレスな統合を実現します。

- 「CWB-2L は当社の 120 馬力トラクターで安定して動作し、大きな傷を付けることなく 2 列をきれいに刈り取ってくれます。」 – オランダ、フレヴォラント州の農家。

- 「早生のジャガイモを時速3kmで問題なく処理し、トレーラーへの排出もスムーズです。」 – ベルギー、西フランダースの協同組合員。

- 「140馬力で混合畑に最適。さまざまな畝間隔に合わせて簡単に調整できます。」 – ドイツ、ニーダーザクセン州の請負業者。

- 「粘土質の土壌でも問題なく動作し、古い単列機械に比べて時間を節約できます。」 – オランダ、北ブラバント州の栽培者。

- 「パワーの割に性能は良好で、ジャガイモをほとんど傷めずにきれいに収集します。」 – フランス、オー=ド=フランスのオペレーター。