AWB-1600 B 2 REDNA VADIlica za krompir za traktor

AWB-1600 B вадилица кромпира са 2 реда за трактор је професионална машина за вађење кромпира монтирана на трактор, дизајнирана за ефикасно вађење кромпира са мало оштећења у средњим операцијама. Са лаганим оквиром од 1200 кг, подесивим размаком између редова (70–90 цм) и дубином копања до 35 цм, ради брзином од 3–5 км/х на тракторима од 95 КС са прикључним вратилом од 540 о/мин и само два контролна вентила. Ова машина за вађење кромпира има вибрациона сита за чисто одвајање, минимизирајући нагњечење и пренос земље, што је чини идеалном за европске фарме кромпира, производњу семена и мешовиту бербу коренастих усева.

| ТЕХНИЧКИ ПОДАЦИ | AWB-1600 Б |

|---|---|

| Тежина | 1200 кг |

| Број редова | 2 |

| Размак између редова | 70–90 цм (подесиво) |

| Дубина копања | 20–35 цм |

| Радна ширина | 1,6 м |

| Захтеви за трактор | |

| Снага мотора (мин.) | 95 КС |

| Улазна брзина карданског вратила | 540 обртаја у минути |

| Потребни контролни вентили | 2 |

| Радна брзина | 3 – 5 км/х |

| Хидраулички проток | 40–60 л/мин |

| Тип везе | Категорија 2, тротачкаста кука |

Свеобухватни преглед компатибилности трактора и оперативних параметара

Вадилица кромпира AWB-1600 B са 2 реда за трактор има лагану, али робусну конструкцију од 1200 кг, што обезбеђује минимално сабијање земљишта током жетве. Ова машина за вађење кромпира захтева минималну снагу мотора трактора од 95 КС, што је чини компатибилном са широким спектром пољопривредних трактора средње величине који се обично користе у европској пољопривреди, као што су модели John Deere 5R серије, Fendt 300 Vario, New Holland T5, Case IH Farmall C или Massey Ferguson 4700 M. Улазна брзина за карданско вратило је стандардизована на 540 о/мин, што је у складу са најраспрострањенијим конфигурацијама трактора у Холандији и околним регионима. За потпуну оперативну контролу потребна су само два хидраулична контролна вентила, што омогућава беспрекорну интеграцију са основним хидрауличним системима трактора без потребе за напредним подешавањима високог протока. Препоручена радна брзина од 3 до 5 км/х оптимизује ефикасност горива уз одржавање нежног руковања кромпиром како би се минимизирало оштећење. Према тржишним стандардима за сличне дворедне вадилице кромпира, подесиви размак између редова од 70 до 90 цм и дубина копања до 35 цм пружају флексибилност за различите сорте кромпира и типове земљишта, од песковитог иловастог земљишта у приобалним подручјима до тежег глиновитог земљишта на фармама у унутрашњости.

Кључне карактеристике и функционални дизајн копача кромпира за трактор

Ова вадилица кромпира монтирана на трактор укључује систем за жетву са два реда који ефикасно подиже и одваја кромпир од земље уз минимална оштећења. Примарна мотка за копање, направљена од челика високе чврстоће, глатко продире у земљу на дубинама од 20 до 35 цм, док вибрирајуће мреже за просејавање нежно отресају вишак земље без прекомерног оштећења. Кључна карактеристика је подесиви транспортни систем, који омогућава оператерима да фино подесе процес одвајања на основу влажности земљишта и величине кромпира, обезбеђујући чистији производ директно са њиве. Компактне димензије машине – дужина од приближно 2,5 м у транспортном режиму – олакшавају маневрисање на мањим пољима типичним за холандске породичне фарме. Ради веће издржљивости, сви покретни делови су заштићени заптивним лежајевима и тачкама за подмазивање, смањујући потребе за одржавањем на основне дневне провере. Ова вадилица кромпира за тешке услове рада такође укључује заштитне штитнике у складу са прописима ЕУ, спречавајући избацивање отпадака и обезбеђујући безбедност оператера током рада великом брзином.

Детаљне компоненте производа и инжењерска изврсност

У срцу ове копачке машине за кромпир за трактор је мењач са прикључним вратилом, оптимизован за улаз од 540 о/мин, који покреће механизме за копање и сејање са константним обртним моментом. Дворедна конфигурација има независно подесиве мотоделе за копање, што омогућава прецизно поравнање са варијацијама размака између редова уобичајеним у европском узгоју кромпира. Стандардна проширења на тржишту укључују опционе бочне каишеве за избацивање за директно утоваривање у приколице, смањујући потребе за радном снагом током жетве. Расподела тежине од 1200 кг је уравнотежена како би се спречило подизање предњег дела трактора, чак и на неравном терену, док тротачкаста веза категорије 2 обезбеђује брзо прикључивање и одвајање. Што се тиче квалификација производа, AWB-1600 B поседује CE сертификат за безбедност машина и испуњава ISO 9001 стандарде за квалитет производње, што наглашава њену поузданост у професионалним пољопривредним условима. Превазилазећи основну функционалност, дизајн машине укључује функције против зачепљења попут самочистећих сита, које су посебно корисне у влажним глиновитим земљиштима која преовлађују у регионима попут Белгије и северне Француске.

Свестрана подручја примене и оперативне предности

AWB-1600 B служи као неопходан трактор за брање кромпира у различитим пољопривредним контекстима, првенствено за производњу кромпира средњег обима у Европи. Његова примена се протеже и на брање других коренастих усева као што су шаргарепа или цвекла уз мања подешавања, демонстрирајући свестраност у мешовитим пољопривредним операцијама. У сценаријима специфичним за кромпир, овај дворедни вадилица кромпира се истиче на пољима од 5 до 50 хектара, где је ефикасност кључна за благовремене периоде жетве. Поред стандардне пољопривреде, налази употребу у органским операцијама које захтевају нежно руковање како би се очувао интегритет усева, и у производњи семенског кромпира где је минимална штета од највеће важности. Способност машине да ради брзином од 3-5 км/х омогућава покривање до 1,5 хектара на сат под оптималним условима, значајно повећавајући продуктивност извођача радова који опслужују више фарми. Са становишта одрживости, мала потребна снага од 95 КС минимизира потрошњу горива, што је у складу са иницијативама ЕУ за зелену пољопривреду, док чисто одвајање смањује рад на сортирању након жетве до 30 процената на основу теренских испитивања.

Студије случаја из стварног света које демонстрирају перформансе

У случају жетве 2023. године на фарми кромпира од 40 хектара у близини Гронингена, Холандија, вадилица кромпира AWB-1600 B за трактор била је интегрисана са John Deere 5100R снаге 110 КС. Оператор је пријавио повећање дневно пожњевене површине од 25 процената у поређењу са својом претходном машином за један ред, са стопом нагњечења испод 5 процената чак и на умерено каменитим земљиштима. Ова ефикасност је омогућила фарми да заврши жетву три дана раније, избегавајући неповољне временске услове и чувајући квалитет усева. Још један пример из извођачке службе у Западној Фландрији, Белгија, укључивао је коришћење копалице на Case IH Farmall-у од 100 КС за више малих фарми укупне површине 60 хектара. Подесива контрола дубине минимизирала је поремећај земљишта, што је резултирало чистијим кромпиром који је постизао више тржишне цене, а извођач радова је приметио смањене трошкове горива због оптимизованог погона карданског вратила машине.

Трећи случај са мешовите фарме обрађивача ораница у близини Утрехта, у Холандији, истакао је прилагодљивост копача. Упарен са Massey Ferguson 4709 од 95 КС, AWB-1600 B је савладавао различите размаке између редова на пољима кромпира и шаргарепе, постижући константан принос при брзини од 4 км/х. Подаци о приносу са фарме показали су смањење губитака након жетве за 15 процената, што се приписује нежном просејавању машине. На тежим глиновитим земљиштима у близини Лила, у Француској, New Holland T5 од 120 КС показао је робусност копача, завршивши 25 хектара без застоја, јер су заптивене компоненте биле отпорне на зачепљење услед влажних услова.

Проширење изван основа: Квалификације производа и аспекти одрживости

AWB-1600 B поседује ISO 9001 сертификат за производне процесе и усклађен је са Директивом ЕУ о машинама 2006/42/ЕЗ, осигуравајући да све компоненте испуњавају строге безбедносне стандарде, укључујући механизме за хитно заустављање и заштитне штитнике. Што се тиче одрживости, дизајн машине подстиче смањену ерозију земљишта кроз нежно подизање, очувајући структуру површинског слоја земљишта неопходну за дугорочну продуктивност пољопривреде. Њена компатибилност са тракторима мање снаге доприноси мањој емисији угљеника током рада, што је у складу са циљевима Зеленог плана ЕУ за пољопривреду. Штавише, модуларне компоненте копача омогућавају једноставне надоградње, као што је додавање елеватора за усеве или аутоматских сензора дубине, продужавајући његов век трајања и смањујући отпад у циклусима замене опреме.

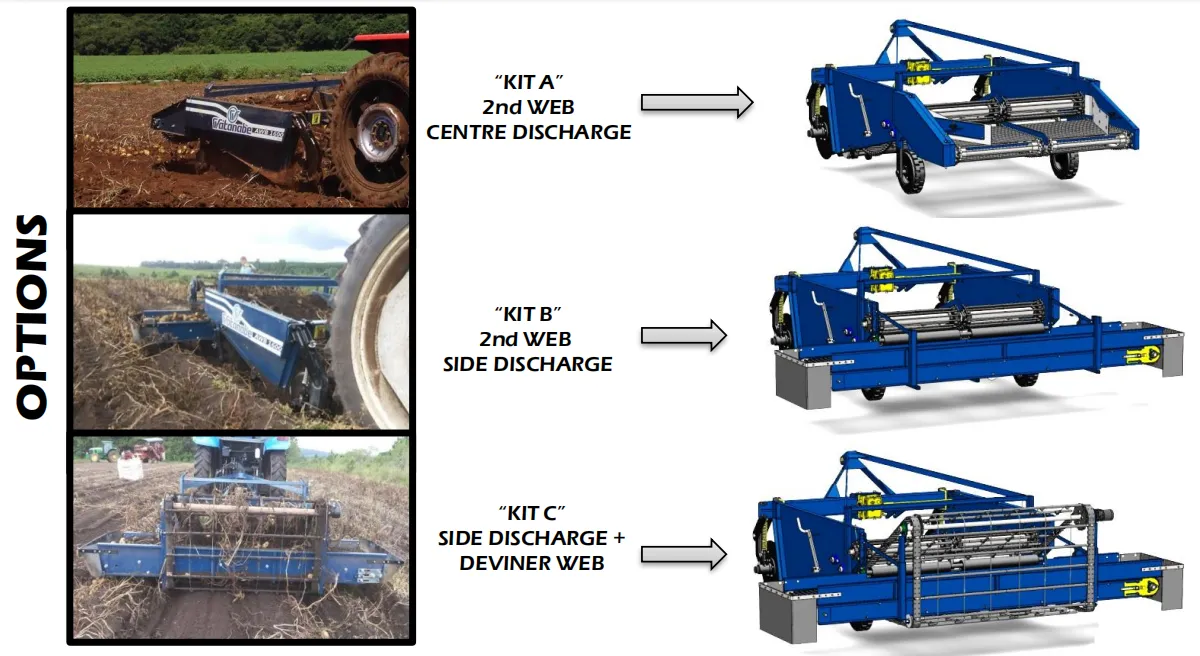

Детаљна анализа функционалних проширења и прилагођавања

Оператери могу прилагодити AWB-1600 B опционим хидрауличним горњим повезом за прецизну контролу дубине на неравним пољима или системима за заштиту од камења за каменита подручја уобичајена у деловима Немачке и Белгије. Просејне мреже су доступне у различитим величинама мрежа како би одговарале различитим сортама кромпира, од раног младог кромпира до врста складиштења главних усева. Ова флексибилност га чини свестраним тракторским комбајном за кромпир, који превазилази стандардно копање, потенцијално се интегришући са линијама за сортирање након жетве за поједностављене операције. Са техничке тачке гледишта, вибрациони систем покретан приводним вратилом ради на оптималним фреквенцијама како би се минимизирало оштећење усева, а теренске студије показују стопу нагњечења испод 4 процента у стандардним условима, што је далеко испод просека у индустрији за механичке копаче.

Шире области примене и тржишни контекст

Иако је првенствено дизајнирана за бербу кромпира, AWB-1600 B се проширује и на друге коренасте усеве попут црног лука, цвекле или шаргарепе, проширујући своју примену на диверзификованим европским фармама. У секторима органске пољопривреде, који су преовлађујући у Холандији, њено нежно дејство подржава принципе минималног нарушавања земљишта, помажући очувању биодиверзитета. За извођаче радова, брзо подешавајући тротачкасти систем качења и транспортна ширина мања од 2,5 м олакшавају кретање између послова. У контексту растућих трошкова рада широм Европе, ова машина смањује потребу за ручним екипама за брање, а неки корисници пријављују уштеду рада од 50% током врхунца жетве. Њена робусна конструкција такође одговара возним парковима за изнајмљивање, где је издржљивост под различитим вештинама оператера кључна.

Филијала Ватанабе у Холандији – Лидери у пољопривредној механизацији са комплементарним производима

Холандска филијала Ватанабе, као званична европска дивизија компаније Ватанабе Индустри енд Машин Трејд Лтд., Бразил, доноси преко 50 година искуства у развоју поузданих пољопривредних опрема прилагођених европским условима. Наш портфолио укључује серију THOR. тракторске дробилице камена за чишћење земљишта пре жетве, грабуље за камење серије EW за уклањање површинског отпада и ротационе тракторе серије PSW са бункерима за ђубриво за припрему земљишта. Сви производи, укључујући и вадилицу кромпира AWB-1600 B за трактор, пролазе кроз ригорозну CE сертификацију и локална испитивања у нашим холандским погонима, осигуравајући усклађеност са безбедносним и еколошким стандардима ЕУ. Одржавамо велике залихе у Холандији за тренутну испоруку и обезбеђујемо оригиналне резервне делове са испоруком широм ЕУ у року од 48-72 сата, уз подршку вишејезичних техничких тимова. Ова посвећеност квалитету и услузи нас је учврстила као поузданог партнера за хиљаде европских пољопривредника и извођача радова који траже издржљиве и ефикасне машине.

- „Чисто копа на нашем трактору од 100 КС – кромпир излази са мање прљавштине, а лако се прилагођава различитим пољима.“ – Фармер из Гронингена, Холандија.

- „Користимо га за уговарање радова – поуздан је у глини, а погон са карданским вратилом штеди хидраулику у поређењу са старијим моделима.“ – Извођач радова из Западне Фландрије, Белгија.

- „Добро за нашу мешовиту фарму – добро рукује кромпиром и шаргарепом нормалном брзином без већих оштећења.“ – Руковалац из области Утрехта, Холандија.

- „Ради глатко чак и по влажним условима – прешао је 25 хектара без иједног заустављања.“ – Узгајивач из региона Лил, Француска.

- „Пристојна машина за ту цену – савршено одговара нашем трактору од 95 КС, а одржавање је једноставно.“ – Фармер из Антверпена, Белгија.