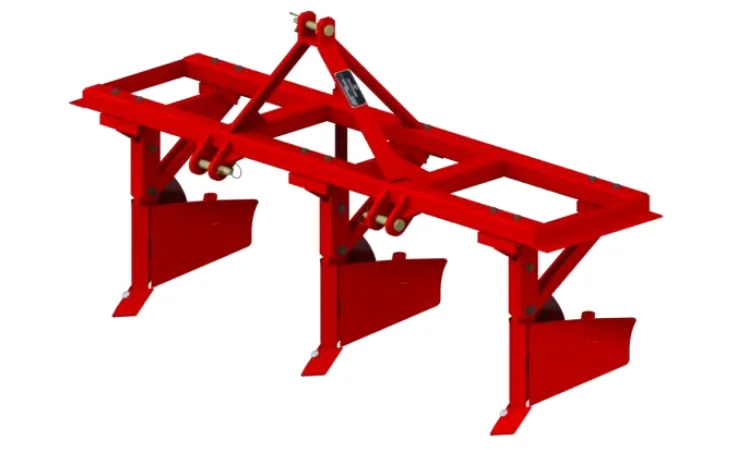

Pług do ziemniaków R-380 z 3 rzędami

Trzyrzędowa glebogryzarka do ziemniaków R-380 to precyzyjnie zaprojektowana, montowana na ciągniku maszyna, która tworzy równomierne redliny dla optymalnej uprawy ziemniaków. Kompatybilna z ciągnikami o mocy minimum 75 KM, charakteryzuje się regulacją głębokości do 30 cm, zaczepem kategorii 2 oraz lekką konstrukcją o masie 500 kg, co minimalizuje zagęszczenie gleby, a jednocześnie poprawia drenaż, rozwój korzeni i plony na różnych typach gleb europejskich.

| DANE TECHNICZNE | R-380 |

|---|---|

| Specyfikacje ogólne | |

| Masa własna | 500 kg |

| Kategoria dolnego łącznika | Kategoria 2 |

| Liczba bruzdowników | 3 |

| Szerokość robocza | 3,8 m (regulowany rozstaw rzędów 70-80 cm) |

| Głębokość bruzdy | Do 30 cm (regulowany) |

| Materiały budowlane | Rama ze stali o wysokiej wytrzymałości ze wzmocnionymi zębami |

| Wymagania dotyczące ciągnika | |

| Minimalna moc silnika | 75 KM |

| Prędkość robocza | 5 - 8 km/h |

| Prędkość WOM | Nie wymagane (narzędzie pasywne) |

| Wymagania hydrauliczne | Opcjonalnie do regulacji; 1-2 zawory dwustronnego działania |

Trzyrzędowa glebogryzarka do ziemniaków R-380 to solidne, montowane na ciągniku narzędzie, przeznaczone do tworzenia precyzyjnych redlin i bruzd do sadzenia i uprawy ziemniaków. Jako wiodąca glebogryzarka do ziemniaków na rynku europejskim, maszyna ta doskonale formuje równomierne redliny glebowe, co sprzyja lepszemu drenażowi, rozwojowi korzeni i plonom. Wykonana z wysokowytrzymałej stali i zaprojektowana z myślą o trwałości, glebogryzarka R-380 łączy w sobie prostotę i wydajność, co czyni ją niezbędnym narzędziem dla nowoczesnych plantatorów ziemniaków i usługodawców. Dzięki regulowanym funkcjom i kompatybilności ze standardowymi ciągnikami, stanowi ona mądrą inwestycję w efektywne przygotowanie pola.

Zgodność ciągnika i wymagania dotyczące mocy

Obsypnik do ziemniaków R-380 jest zoptymalizowany pod kątem ciągników o minimalnej mocy silnika 75 KM, dzięki czemu jest dostępny dla szerokiej gamy średniej wielkości ciągników użytkowych powszechnie stosowanych w rolnictwie europejskim. Wyposażony jest w dolny zaczep kategorii 2, zapewniający bezpieczne i stabilne mocowanie do modeli takich jak John Deere serii 5R, New Holland T5, Case IH Farmall, Fendt 300 Vario, Massey Ferguson 5700 czy Valtra serii A. Ten obsypnik do ziemniaków nie wymaga użycia WOM, działając jako narzędzie pasywne ciągnięte z prędkością roboczą od 5 do 8 km/h, co zapewnia optymalną wydajność formowania redlin. Dla zwiększenia możliwości regulacji, może on wykorzystywać 1-2 zawory hydrauliczne dwustronnego działania z ciągnika, umożliwiając modyfikację wysokości lub szerokości redliny w locie, bez zatrzymywania się. Taka kompatybilność obniża koszty operacyjne i pozwala rolnikom na zakup obsypnika do ziemniaków, który bezproblemowo integruje się z istniejącym sprzętem, eliminując potrzebę stosowania specjalistycznych ciągników o dużej mocy.

Standardy rynkowe dla podobnych 3-rzędowych oraczy kładą nacisk na wszechstronność, a model R-380 idealnie się do tego nadaje, umożliwiając regulację rozstawu rzędów w zakresie od 70 do 80 cm, co pozwala na pracę z różnymi odmianami ziemniaków i różnymi rodzajami gleby. Niska masa własna, wynosząca 500 kg, minimalizuje ugniatanie gleby i obciążenie ciągnika, nawet na miękkim podłożu, jednocześnie zapewniając stabilność podczas pracy z dużą prędkością. Dla osób poszukujących opcji cenowych dla oraczy do ziemniaków, ten model oferuje doskonały stosunek jakości do ceny, przy niskich wymaganiach konserwacyjnych dzięki prostej konstrukcji mechanicznej i braku skomplikowanego układu hydraulicznego lub napędu WOM.

Główne cechy i funkcje R-380

Sercem 3-rzędowej bruzdownicy do ziemniaków R-380 jest wydajny system formowania redlin, składający się z trzech wytrzymałych bruzdowników, które tworzą symetryczne redliny o jednakowej głębokości i kształcie. Podstawową funkcją maszyny jest formowanie podniesionych redlin, które poprawiają napowietrzenie gleby, odprowadzanie wody i regulację temperatury – czynniki kluczowe dla rozwoju bulw ziemniaka. Każda bruzdownica jest wyposażona we wzmocnione zęby, które penetrują glebę na głębokość do 30 cm, rozbijając bryły i mieszając resztki pożniwne, zapewniając dobrą glebę. Ta ciągnikowa bruzdownica do ziemniaków wspomaga również zwalczanie chwastów, zakopując nasiona w bruzdach, co zmniejsza potrzebę stosowania herbicydów w zrównoważonych praktykach rolniczych.

Wychodząc poza podstawowe funkcje obsypywania redlin, R-380 posiada regulowane elementy do regulacji wysokości i szerokości redlin, co pozwala na dostosowanie ich do warunków glebowych lub wymagań upraw. Na przykład, na cięższych glebach gliniastych, powszechnych w Holandii, użytkownicy mogą ustawić szersze redliny, aby poprawić drenaż, podczas gdy na piaszczystych glinach węższe konfiguracje optymalizują zatrzymywanie wilgoci. Pasywna konstrukcja narzędzia eliminuje potrzebę użycia wału odbioru mocy, upraszczając konfigurację i zmniejszając zużycie paliwa nawet o 20% w porównaniu z alternatywnymi rozwiązaniami z napędem. Jako 3-rzędowa obsypnica do ziemniaków, obrabia ona jednocześnie trzy rzędy, pokrywając do 3,8 m szerokości, co zwiększa wydajność w gospodarstwach średniej wielkości.

Szczegółowe specyfikacje produktu i innowacje

Model R-380 charakteryzuje się kompaktową, a zarazem solidną konstrukcją o wymiarach 2300 mm długości, 3545 mm szerokości i 2530 mm wysokości, co zapewnia łatwy transport i przechowywanie. Masa własna maszyny, wynosząca 500 kg, została osiągnięta dzięki zastosowaniu wysokiej jakości stali odpornej na korozję i zużycie, co wydłuża żywotność maszyny do ponad 10 lat przy prawidłowej konserwacji. Do najważniejszych innowacji należą zęby sprężynowe, które dostosowują się do nierówności terenu, zapobiegając uszkodzeniom i zapewniając równomierne redliny. Obory są wyposażone w wymienne części eksploatacyjne, co minimalizuje przestoje i koszty napraw – cechę docenianą przez użytkowników poszukujących wytrzymałych rozwiązań do obory ziemniaków.

Model R-380 spełnia unijne normy bezpieczeństwa i ochrony środowiska CE, dzięki zastosowaniu osłon chroniących operatorów i cichej pracy. Posiada certyfikat do stosowania w rolnictwie ekologicznym, ponieważ jego działanie mechaniczne eliminuje pozostałości środków chemicznych. Dla osób poszukujących szczegółowych informacji na temat formowaczy do ziemniaków, regulowany rozstaw rzędów modelu R-380 wspomaga rolnictwo precyzyjne, integrując się z ciągnikami sterowanymi przez GPS, co zapewnia proste i wydajne formowanie redlin. Ten poziom szczegółowości podkreśla zaangażowanie firmy Watanabe w jakość – każda jednostka przechodzi rygorystyczne testy przed wysyłką z naszego zakładu w Holandii.

Obszary zastosowań i wszechstronne zastosowania

Brona do ziemniaków R-380 znajduje zastosowanie przede wszystkim w uprawie ziemniaków, gdzie przygotowuje idealne grządki do sadzenia, obsypywania i przygotowania do zbiorów. W regionach Holandii, gdzie ziemniaki są powszechne, służy do formowania redlin, chroniących bulwy przed mrozem i nadmiarem wody. Oprócz ziemniaków, ten wszechstronny 3-rzędowy kultywator sprawdza się również w uprawie innych roślin okopowych, takich jak marchew, buraki i cebula, tworząc bruzdy ułatwiające zbiór mechaniczny. W ogrodnictwie wspomaga kształtowanie wysokich grządek w ogrodach warzywnych i na polach kwiatowych.

Rozszerzając swoją funkcjonalność, R-380 sprawdza się w projektach ochrony gleby, takich jak formowanie redlin w celu zapobiegania erozji na zboczach w belgijskich Ardenach lub na pagórkowatych terenach Niemiec. W ramach zrównoważonych praktyk, R-380 wprowadza zielony nawóz lub rośliny okrywowe do redlin, poprawiając kondycję gleby. Wykonawcy często wynajmują trzyrzędowe bruzdowniki do ziemniaków, ze względu na ich zdolność adaptacji do różnych rodzajów gleby – od piaszczystych gleb nadmorskich po gliniaste pola śródlądowe. To szerokie spektrum zastosowań sprawia, że R-380 jest podstawą europejskiego rolnictwa, wspierając zarówno konwencjonalne, jak i ekologiczne metody uprawy.

Studia przypadków z życia wzięte, demonstrujące wydajność

Na 200-hektarowej farmie ziemniaków niedaleko Amsterdamu, maszyna R-380 została zamontowana na ciągniku o mocy 90 KM, tworząc redliny z prędkością 6 km/h i skracając czas sadzenia o 25%. Jednorodne bruzdy doprowadziły do 15% wzrostu jednolitości wielkości bulw, co zostało odnotowane w analizie plonów w gospodarstwie. Inny przypadek na polach wokół Brukseli dotyczył uprawy marchwi; regulowana głębokość zapobiegała zagęszczaniu gleby, co skutkowało prostszymi korzeniami i wzrostem plonów o 10%. W berlińskich gospodarstwach ekologicznych maszyna R-380 ułatwiła bezchemiczne zwalczanie chwastów poprzez precyzyjne formowanie redlin, co jest zgodne z unijnymi standardami zrównoważonego rozwoju i spotkało się z pozytywnymi opiniami audytorów.

Watanabe Netherlands: Liderzy w dziedzinie maszyn do uprawy ziemniaków i kompleksowych rozwiązań rolniczych

Watanabe Netherlands, europejski oddział firmy Watanabe Industry and Machine Trade Ltd., posiada ponad 50 lat doświadczenia w produkcji narzędzi rolniczych, a w szczególności maszyn do zbioru ziemniaków, takich jak R-380 Furrower, THOR Kruszarki do kamieni ciągnikowych, zgrabiarki EW i glebogryzarki PSW. Nasz magazyn w Holandii gwarantuje szybką dostawę i dostępność oryginalnych części w całej Europie, a także wielojęzyczne wsparcie techniczne. Stawiając na innowacyjność, oferujemy produkty z certyfikatem CE, spełniające rygorystyczne normy UE, budując zaufanie tysięcy rolników i wykonawców.

- „Na naszym 80-konnym traktorze tworzy ładne, równe redliny – pola wyglądają dobrze, a ziemniaki rosną prosto.” – Rolnik z Amsterdamu w Holandii.

- „Używałem go do uprawy marchwi – regulacja głębokości działa dobrze, w tym roku nie było problemów z zagęszczaniem gleby.” – Plantator z Brukseli, Belgia.

- „Przyzwoita maszyna do produkcji grządek organicznych – redliny zachowują kształt nawet po deszczu.” – Kierownik z Berlina, Niemcy.

- „Pracuje płynnie przy prędkości 7 km/h, oszczędza czas przy przygotowaniach do wiosny.” – Operator z Rotterdamu, Holandia.

- „Doskonałe do naszych pochyłych pól – stabilne i łatwe w regulacji.” – Wykonawca z Paryża, Francja.