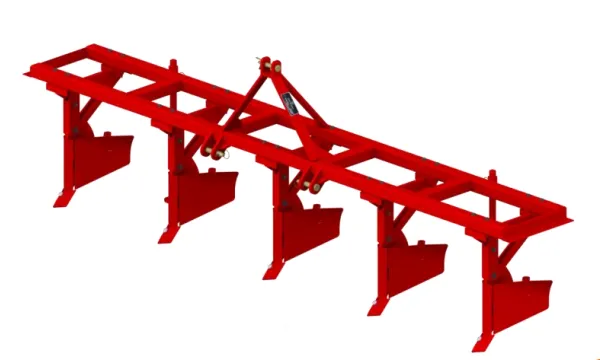

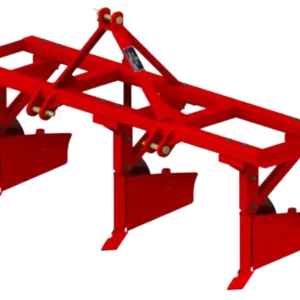

محراث ريجر لثلم البطاطس ذو 5 صفوف R-580

محراث R-580 ذو الخمسة صفوف لزراعة البطاطس هو أداة احترافية تُركّب على الجرار، مصممة لتشكيل تلال دقيقة في زراعة البطاطس والمحاصيل الصفية. مُحسّن للجرارات ذات قوة 85-120 حصانًا مع وصلة من الفئة 2، ويتميز بخمسة أخاديد قابلة للتعديل تُنشئ تلالًا متجانسة (بمسافة 70-80 سم بين الأخاديد، وارتفاع 15-30 سم) بسرعة 5-8 كم/ساعة، مما يُحسّن تهوية التربة وتصريفها وإنتاجيتها، مع تقليل الحاجة إلى ضغط التربة والصيانة.

| البيانات الفنية | R-580 |

|---|---|

| الوزن والسعة | |

| الوزن الفارغ | 620 كجم |

| الوزن الإجمالي (تقديري، وفقًا لمعايير السوق) | 750-850 كجم |

| التفاصيل الهيكلية | |

| فئة الارتباط السفلي | القط 2 |

| عدد الأخاديد | 5 |

| تباعد الصفوف (قابل للتعديل، وفقًا لمعايير السوق) | 70-80 سم |

| ارتفاع الحافة (قابل للتعديل، وفقًا لمعايير السوق) | 15-30 سم |

| قطر القرص (المعيار السوقي) | 50-60 سم |

| متطلبات الجرار | |

| قوة المحرك (بالدقائق) | 85 حصان |

| سرعة العمل | 5-8 كم/ساعة |

| متطلبات PTO (المعيار السوقي) | لا شيء (أداة سلبية) |

| يلزم وجود أجهزة تحكم هيدروليكية عن بعد (وفقًا لمعايير السوق) | لا أحد |

التوافق الأمثل للجرارات مع محراث R-580 لزراعة البطاطس

صُمم محراث R-580 ذو الخمسة صفوف لتحضير أخاديد البطاطس للجرارات متوسطة القدرة بدءًا من 85 حصانًا، مما يجعله في متناول المزارع العائلية والمقاولين الصغار في جميع أنحاء أوروبا. يُركّب هذا المحراث على الجرارات عبر وصلة ثلاثية النقاط من الفئة الثانية، مما يضمن توافقه التام مع الطرازات الشائعة مثل John Deere 5M series وNew Holland T5 وCase IH Farmall C وFendt 300 Vario وMassey Ferguson 5700 M وValtra G series. بوزنه الخفيف الذي يبلغ 620 كجم فقط، يُقلل محراث البطاطس الضغط على المحور الخلفي للجرار، مما يسمح بتشغيله بكفاءة حتى مع الجرارات التي تتراوح قدرتها بين 90 و110 حصانًا في معظم أنواع التربة. لا يتطلب هذا المحراث عمود إدارة الطاقة أو أي وصلات هيدروليكية خارجية، فهو يعمل بشكل تلقائي بالكامل - ما عليك سوى رفعه وخفضه وسحبه بسرعة تتراوح بين 5 و8 كم/ساعة لتحضير أخاديد مثالية. بالنسبة للتربة الطينية الثقيلة أو التضاريس الجبلية، نوصي باستخدام جرارات بقوة 100 حصان أو أكثر للحفاظ على السرعة المثلى وثبات العمق. هذا الاحتياج المنخفض للطاقة يجعل من R-580 خيارًا اقتصاديًا مناسبًا للمزارعين الراغبين في شراء محراث لتسوية حقول البطاطس، وذلك للترقية من المحراث اليدوي أو المحراث ذي الثلاثة صفوف الأصغر حجمًا.

الميزات الأساسية والتصميم الوظيفي لمحراث R-580 لزراعة البطاطس

تتميز محراث R-580 بقوته ومتانته، فهو محراث متعدد الصفوف مصمم خصيصًا لتشكيل تلال دقيقة في زراعة البطاطس والمحاصيل الصفية المشابهة. يحتوي على خمسة أخاديد قابلة للتعديل، مما يُتيح إنشاء تلال متجانسة بارتفاعات تتراوح بين 15 و30 سم، وبمسافة بين الصفوف تتراوح بين 70 و80 سم (وهو المعيار السائد في السوق لأصناف البطاطس الأوروبية). تشق أقراصه المتينة، التي يتراوح قطرها بين 50 و60 سم، التربة بسلاسة مع تقليل تكوّن الكتل، مما يضمن دورانًا مثاليًا للهواء وتصريفًا فعالًا للمياه حول الدرنات. صُنع المحراث من فولاذ عالي القوة مع عوارض مُدعمة، مما يجعله يتحمل الاستخدام الشاق في مختلف أنواع التربة الأوروبية، من التربة الرملية الطينية في هولندا إلى الحقول الطينية في بلجيكا. تشمل الميزات الوظيفية الرئيسية إمكانية تعديل عرض التلال يدويًا أو هيدروليكيًا (اختياري) لمزيد من التنوع، بالإضافة إلى تصميمات مضادة للانسداد على الأقراص للتعامل مع الحقول الغنية بالمخلفات دون توقف. لا يقتصر دور هذه الآلة الزراعية لتجهيز الأحواض فحسب، بل إنها تتضمن أيضًا مكافحة الأعشاب الضارة السطحية، مما يجعلها أداة متعددة الوظائف لممارسات الزراعة المستدامة.

تفاصيل المنتج الموسعة: المتانة، الصيانة، والشهادات

إلى جانب وظائفها الأساسية، تتميز محراث R-580 لتسوية أخاديد البطاطس بمكونات عالية الجودة تضمن متانته على المدى الطويل. هيكله مطلي بمسحوق مقاوم للتآكل، مما يجعله مثاليًا للمناخات الأوروبية الرطبة، بينما محاملها محكمة الإغلاق وقابلة للتشحيم لسهولة الصيانة، حيث لا تتطلب عادةً سوى فحوصات سنوية. تساهم تفاصيل المنتج، مثل قطع الغيار القابلة للاستبدال في الأخاديد، في خفض التكاليف على المدى الطويل، إذ صُمم كل قرص ليدوم من 500 إلى 800 هكتار قبل استبداله. وباعتباره جزءًا من مجموعة منتجات واتانابي الحاصلة على شهادة CE، فإن هذا المحراث ذو الخمسة صفوف يفي بجميع معايير السلامة في الاتحاد الأوروبي، بما في ذلك الأجزاء المتحركة المحمية وهندسة الربط الثابتة لمنع الانقلاب. بالنسبة للمزارعين المهتمين بالبيئة، يُسهم تصميم هذه الآلة في تقليل ضغط التربة مقارنةً بالبدائل الأثقل، بما يتماشى مع معايير الزراعة المستدامة بموجب إرشادات السياسة الزراعية المشتركة (CAP). عند النظر في سعر محراث تسوية أخاديد البطاطس، يُقدم R-580 قيمة استثنائية بفضل قلة احتياجاته للصيانة وإمكانية إعادة بيعه العالية في سوق المستعمل.

مجالات التطبيق: من حقول البطاطس إلى تحضير المحاصيل الصفية المتعددة الاستخدامات

صُممت محراث R-580 لزراعة البطاطس خصيصًا لهذا الغرض، حيث يتميز بقدرته الفائقة على إنشاء تلال متناسقة تحمي الدرنات من التلف الأخضر وتُحسّن كفاءة الحصاد. وفي مجالات أخرى غير زراعة البطاطس، يُستخدم هذا المحراث الجرار على نطاق واسع في تجهيز أحواض زراعة الشمندر والجزر والبصل، حيث تُعزز التلال المنتظمة نمو الجذور وتُحسّن التحكم في الري. كما يستخدمه المقاولون في إدارة المحاصيل الغطائية أو حتى في استصلاح الأراضي الخفيف، حيث تُساعد عملية تشكيل التلال على مكافحة التعرية في الحقول المنحدرة. وفي الزراعة العضوية، تُقلل التلال التي يُشكلها المحراث من الاعتماد على مبيدات الأعشاب، بينما في الأنظمة التقليدية، يندمج بسلاسة مع أنظمة الزراعة الدقيقة. وفي العمليات الزراعية الكبيرة، يُغطي المحراث ذو الخمسة صفوف ما يصل إلى 2-3 هكتارات في الساعة بالسرعات الموصى بها، مما يجعله أداة موفرة للوقت. وسواء في الأراضي المستصلحة في هولندا أو التلال المتموجة في ألمانيا، يتكيف هذا المحراث مع مختلف أنواع التضاريس، مما يُثبت تنوعه في الزراعة الأوروبية.

دراسات حالة واقعية توضح أداء R-580

لإبراز كفاءة محراث R-580 لتسوية أخاديد البطاطس، نستعرض حالة من مزرعة بطاطس مساحتها 120 هكتارًا في فليفولاند، هولندا. باستخدام هذه الآلة على جرار بقوة 95 حصانًا، حقق المزارع سرعة أكبر في تشكيل الأخاديد بمقدار 25% مقارنةً بنموذجه السابق ذي الأربعة صفوف، مما أدى إلى أخاديد أكثر تجانسًا بمقدار 20% وتقليل تعرض الدرنات للضوء، وبالتالي زيادة في المحصول بمقدار 12% في حصاد عام 2024. وفي مثال آخر من تعاونية خضراوات بالقرب من أنتويرب، بلجيكا، استخدم المقاولون محراث R-580 لتحضير أحواض الجزر، مشيرين إلى ثباته في التربة الرملية وقلة تكتل التربة، مما قلل من تأخير الزراعة بيومين لكل 50 هكتارًا. أما الحالة الثالثة من مزرعة مختلطة في ساكسونيا السفلى، ألمانيا، فقد أظهرت متانة المحراث لأكثر من 600 ساعة دون الحاجة إلى إصلاحات كبيرة، حيث تعامل بكفاءة مع التربة الطينية وتكامله مع الجرارات الموجهة بنظام تحديد المواقع العالمي (GPS) لمحاذاة الصفوف بدقة. تؤكد هذه الحالات على سبب اختيار المزارعين الذين يبحثون عن آلة تشكيل بطاطس للبيع غالبًا لآلة R-580 للحصول على نتائج موثوقة ومثبتة ميدانيًا.

واتانابي هولندا: رواد في مجال آلات تجهيز الأراضي مع مجموعة كاملة من المنتجات التكميلية

يقدم فرع واتانابي في هولندا، بصفته الذراع الأوروبي الرسمي لشركة واتانابي للصناعة وتجارة الآلات المحدودة في البرازيل، خبرة تزيد عن 50 عامًا في مجال المعدات الزراعية للمزارعين والمقاولين في جميع أنحاء القارة. ولا تقتصر منتجاتنا على محراث R-580 لحصاد البطاطس، بل تشمل منتجات تكميلية مثل سلسلة THOR. آلة تكسير الحجارة لتجهيز الأرض في المراحل الأولى، نستخدم مجارف صخرية لإزالة المخلفات، ومحاريث دوارة مزودة بخزانات أسمدة لتحسين مهد البذور في المراحل النهائية، مما يخلق بيئة متكاملة لإنتاج البطاطس والمحاصيل الصفية بكفاءة عالية. تخضع جميع معداتنا لشهادة المطابقة الأوروبية (CE) الصارمة، ويتم تكييفها محليًا في مصنعنا بهولندا، لضمان الامتثال والأداء الأمثل في الظروف الأوروبية. بفضل قطع الغيار الأصلية المتوفرة محليًا والدعم الفني متعدد اللغات، نبني الثقة من خلال خدمة ما بعد البيع الموثوقة التي تضمن استمرار عملياتكم بسلاسة.

- "يقوم جهاز R-580 بعمل تلال متساوية وجميلة على جرارنا ذي قوة 90 حصانًا - لا توجد مشاكل حتى في البقع الرطبة." - مزارع بطاطس من فليفولاند، هولندا.

- "استخدمته لزراعة الجزر في الموسم الماضي - خرجت الصفوف مستقيمة والمحراث متين للغاية." - مقاول من منطقة أنتويرب، بلجيكا.

- "بنية متينة لحقولنا الطينية - تنجز المهمة دون الكثير من المتاعب." - مزارع مختلط من ساكسونيا السفلى، ألمانيا.

- "خفيف بما يكفي لجرارنا الصغير ولكنه لا يزال يغطي خمسة صفوف بسرعة." - مزارع خضروات من شمال برابانت، هولندا.

- "آلة جيدة مقابل سعرها - تصريف المياه من التلال أفضل من آلتنا القديمة." - مشغل مزرعة من نورد-با-دو-كاليه، فرنسا.